Making a manifold a Fitting individual throttle bodies to a zetec

This is basically what ive done and as a guide only with no guarantee it will work for you, its brief

for a reason as should be undertaken with a level of engineering knowledge to fill in the gaps (but

will add more detail later).

I currently have fitted early GSXR600 motorbike throttle bodies as have lots of other people and

information readily available for fitting these as they are easily split to re-space to suite the inlet

port spacing’s, the info contained below is a mixture of my current set of GSXR600 and larger work

in progress GSXR750 set.

GSXR600K1 38mm internal diameter

Early GSXR750 40mm internal diameter

The throttle bodies do not necessarily need to be re-spaced it just makes the manufacture of

the manifold easier as there will be no compound curves to manufacture and as using the original

zetec injectors and sandwich plate do not have the added problem of manufacturing/modifying

the fuel rail.

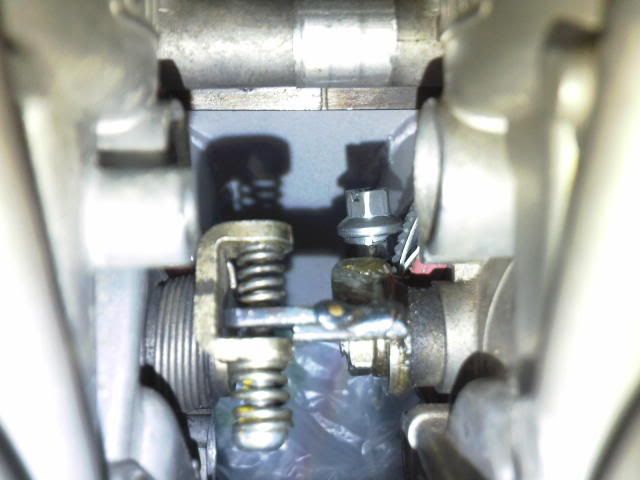

The throttle bodies are individual castings held together on threaded rods, to re-space need to

start with removing the surplus secondary butterfly system, injector fuel rail and unbolt, take

care when pulling apart to retain the throttle linkage springs for re use.

surplus secondary butterflys and rod to be removed

and stepper motor

End up with four individual throttle bodies

The holes where the secondary butterfly’s were removed and GSXR injectors were removed

need to be plugged, I have the luxury of a lath and turned some aluminium interference fit

bungs to plug the orifices.

Then a case of measuring your inlet port spacing’s and making more spacers to suit,

Firstly for the throttle arm linkages need extending where I used 10mm flat steel overlapped

and tack welded on

And more aluminium spaces these slide between the individual throttle bodies with longer

threaded rod and re-bolted together alternative I have also seen is use of extra nuts to re-space.

Once the throttle bodies are done next the inlet manifold.

I started with a steel injector blank plate I got cut from a gasket via shorttrack-motor-sport

(who sell via ebay), note that the injector sandwich plate blank is different from the zetec head

blank

inlet head plate as used for bike carbs (a previous set I made)

Blank required for sandwich plate

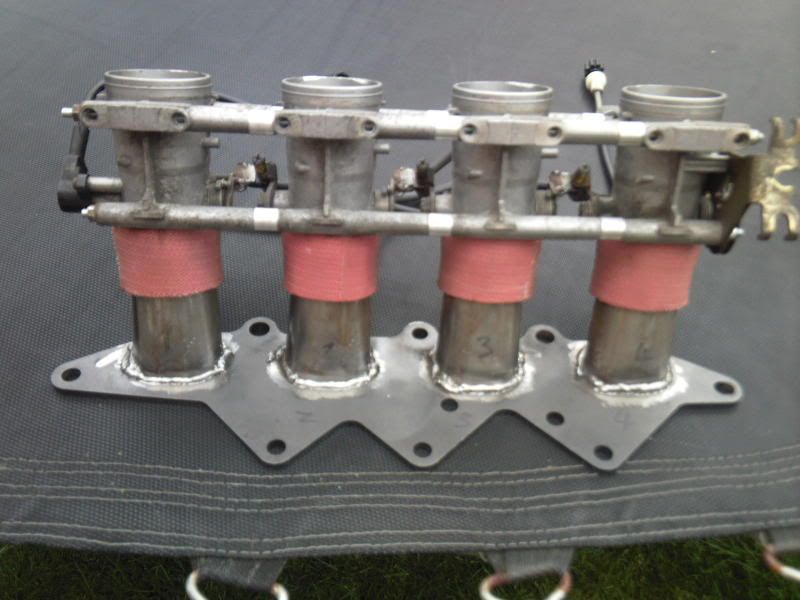

Ive recently made two manifolds first one currently fitted with GSXR600 throttle bodies with a

added bend in the manifold

And latest one with straight headers

Firstly the blank needed a bit of home modification to miss the injectors and also for mounting

hole spacing

Found 44mm external dia 1.2mm wall steel tube works out right for the throttle bodies and oval

inlet ports when squashed.

The tubes were cut at a angle to match the injector plate

Squashed in a vice to oval as inlet port shape and then cut of the length of pipe, I squashed

them when still on long length of pipe to reduce distortion as if cut off to length and then

squashed the whole bit would end up oval.

Once all four cut off assembled the throttle bodies with mounting hoses to align and tacked

together.

Mk2 version

Mk1 version

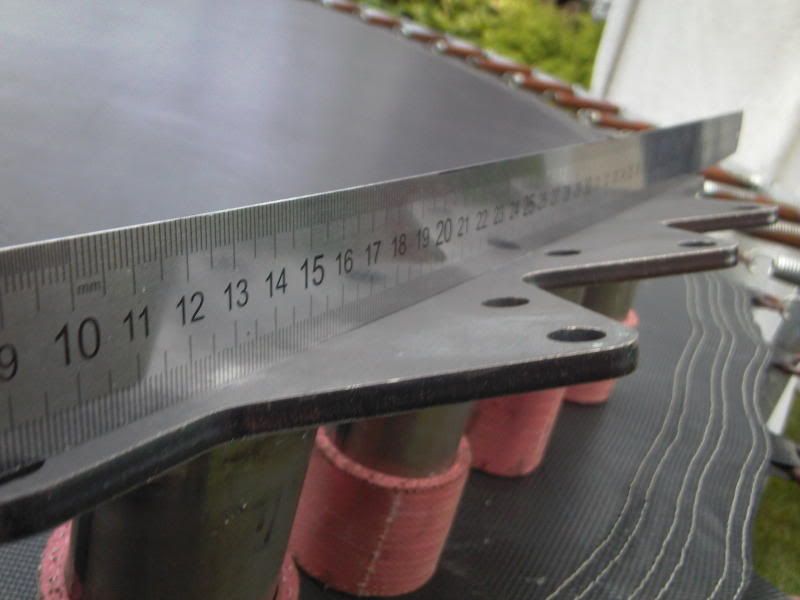

Prior to fully welding I bolted it to a spare injector sandwich plate to deduce distortion, but it still

bowed up about 3mm at each end once unbolted but a few tugs in the vice had it flat enough to

run a file over.

During the squeezing and welding the headers ended up a little bit out of round but a squeeze in

the opposite direction with a pair mole grips had the round enough.

Quick clean up internally of the weld and a check over for leaks

Final assembly

Mk1 version

Mk2 version

Mk1 fitted

Will have to further add details of next stage another time but very brief

As Im currently running with the standard Ford ECU made a Fibre glass plenum to fit with the

MAF produced 150bhp

But the proposal for the Mk2 version is to run replacement programmable ECU with a panel filter.

Lastly the same principal applies to making a manifold for motorbikes carbs, just with a different

manifold blank, this are ones I previously made with ZX9R carbs