wrote this on FT a while ago, it might help on here as theres cvh si's about so if it helps, here ya go

this guide was done for help for a guy that needed it on his xr2i, but its the same for frst also.

the fitment of the pump is the same for all EFI's and CFI's

Before starting any work make sure you have everything your going need to do the jon.

These are the bits I recommend to have or can get very easy (like the same day) to do these jobs.

Fuel pump

New sender unit sealer ring

Copper grease (for when fitting new bolts)

Spare nuts and bolts and washers

WD40

Something to syphen petrol from tank and store it in (if needed)

Jack

Axle stands

Tools

Injectors

New seals 8 for injectors, 1 for regulator

Fuel filter (if your changing it)

WD40

Tool

Rags to soak up petrol

First off you have to depressurise the system, even if your doing 1 or the other, to do this, take the fuse out for the fuel pump, take petrol filler cap off and crank it over a few times, disconnect battery.

you can leave the cap off if you want but don’t need to

make sure you have very little petrol in the tank, if there’s a lot your have to syphen it out other wise your spill it everywhere.

Jack and axle stands are need to gain more room under the car, you don’t need to raise it if you fell you have enough room, but I recommend to raise it a bit, even if you put breeze blocks under the rear wheels that’s a extra 3 inches.

But chock the front wheels, and make sure its safe to go under before you do.

If you plan to have the back high, and not remover the tank from under the car you may need something to rest the tank on save strain on the plastic fuel lines

fitting the pump

Disconnect the wiring plug from the top of the tank but lifting the rear seats and unplugging it.

To drop the tank, you need to disconnect all the pipes from the filler pipe to the tank, some have to be done once tank id off, and the tank can be slid off the filler pipe it self.

Undo the 4 bolts holding the tank up, you may find the back ones will be a pain, sometimes the spring nut snaps so it spins but you can get a spanner of it or wedge a screw driver in to stop it, but once all 4 are off lower the tank, front end first and slide it off filler pipe, if the whole tank is to be removed from under the car disconnect the remaining pipes from the tank.

To remove the fuel pipes from the sender unit, start with the one with the push fit connection, the outer white bit needs to be broken off (unless you have the tool) and you push the small inner white bit in and slide the pipe off as its no different to any other push fitting.

Remover the other pipe and now you can remove the tank from under the car.

If you don’t want to remove the tank from under the car, leave the 2 fuel pipes on the sender unit and proceed to remove the pump taking car not to kink or crack the fuel lines.

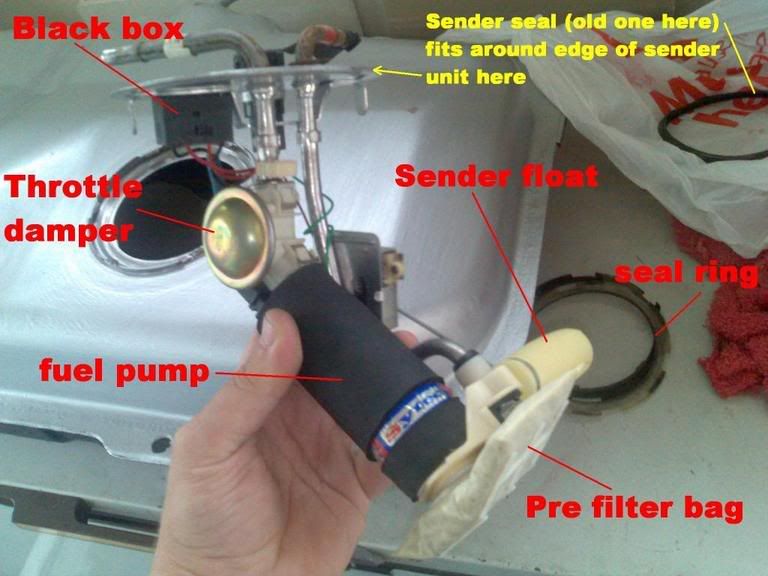

To remove the pump you have to get the whole sender unit out, using a bit of alloy or something (not steel as you don’t want to cause a spark!!!) tap the seal ring round and remove it, pull the sender unit out.

f you want to by pass the black box, cut the red and black wire that’s goes to it and join it the the wires to the pump. (you do not need to bypass this black box if you don’t want to!)

depending on the make of pump the connections could be different to that of ford but the plug for the new pump will/should be with it so good enough. but use protective connections with the plastic on them.

Remove the old pump from the sender unit, careful not to bend the float to the sender, you will need to keep the throttle damper for the new pump so fit that on the new pump.

fit the pump in the cradle and put it back reverse to how you took it out., check the bag at the bottom of the pump is not going to in any way touch the float on the sender , if it does, move it as it will tell you have fuel when in fact you haven’t! As it will keep the float up a little.

before you final fit the tank back, get a mate to fit the fuel pump fuse back in and turn the ignition on (with battery connected of course) to check the pump will prime/work, if it does refit everything in reverse to how it came off, if it don’t, check the fuse, check the batter is connected right, check the sender/fuel pump plug (give it a little wd40if need be) also check the fuel cut off switch which is located in the passenger footwall behind the kick trim, pull the plunger/switch up (off) and press it back down (on) as you want it on, if it don’t come up when you pull it, it means it tripped and just press it back down. if it still don’t work and your getting power to the pump then the pumps naff, but chances of that.....not likely

on the seal that the filler pipe goes into, rub a bit of oil over it to ease fitting the filler pipe back in, only a little will be needed and you can take a drip from the dipstick if you don’t have any spare.

injectors,

going on that the system is de pressurised and battery is disconnected and fuel pump fuse is back out,

you can do it with the top half of inlet manifold on (hard way)

or with it off (easy way)

for ease you can remove the top half of the inlet manifold but a new gasket is recommended for it if you do it this way and I also recommend new injectors seals 100% (if new injectors are fitted new seals should be with them, but get a new one for the regulator just in case)

disconnect throttle cable, do this by opening it by hand on the right side and removing cable, then prize it out with a screw driver from the bracket,

Unplug the TPS plug , the ISCV plug and also the sensor plug on the right hand side of the inlet, remove charge carrier/intake

you will also need to remove the vac pipe that goes to the brake servo, this is done the same way as the fuel pipe, push the little ring part in and pull the pipe out as that to is a push fitting.

there are about 4 nuts along the top back edge of the inlet, remove them, the other ones hold the injector loom on and they have to come off anyway.

depending on which bracket you have holding the throttle cable you might need to remove this, if its one that has a bit going down to the bottom half of the inlet, your need to remove 2 bolts either side of the throttle body, don’t worry if the bracket don’t move as its has another done below but that can stay, if you have a different one like most xr2is, its bolted to the top half only so you don’t have to touch it.

remove the top part of the inlet manifold, unplug all the injectors, and unplug the injector loom and remove (there is a plug that goes to the water temp sensor on the bottom of the inlet that has to be unplugged, and also the wire to the oil pressure switch also so you have to get you hand down the back but this one is just pushed on and pulls off.

just don’t forget to reconnect these when you put it back together

undo the 2 bolts that hole the fuel rail down, and pull off, it will be hard as the injectors are in it but it will come off.

you do not need to remove the fuel pressure regulator, if you do I advise a new seal for this also.

pull out any injectors that ate still in the bottom half, fit the new seals to the new injectors, I advise a dab of oil on each seal to ease fitting it to the injectors but more so to help back into the bottom half of inlet, if you don’t use oil its a focker!

fit injectors in bottom half, refit fuel rail, make sure all injectors have seated right (as far in as they will go) and bolt on fuel rail

from now, fit everything back on as it cam off fitting new gasket to inlet manifold middle, to get what’s left of the old one off you might need to scrape it with a Stanley scrapper/Stanley blade.

when it comes to fitting the vac pipe from servo back on this will just need pushing on like the fuel pipe, it will go so far and stop, that means its on and that’s finished with.

once its all back together, reconnect battery, put petrol in (if you haven’t already) fit fuel pump fuse and prime the system by turning ignition on and off a min of 6 times, turn it once so pump buzzes, when it stops do it again, don’t try and start the car until its primed!!

if you don’t want to do the easy way and you want to leave the top half on, then you have to follow what is above but don’t remove the top half, but I recommend the easy way!

if your going this far, why not replace the fuel filter.

if so, its located on the passenger side inner wing by the battery, leave it in the bracket but undo the bolts both ends as there be tight, once "cracked" you can remove the filter or take the pipes off first, don’t lose the copper washer that sits between the bolt and filter (both ends)

take filter out, fit new one and bolt pipes back on.

if fuel filter is replace I recommend the system is primed a lot more like 12+ times to ensure fuel is up to the injectors.

Please note, the way I have said about priming the system is right, you do not need to disconnect any pipe to bleed air out.

when you come to start it (even if you didn’t replace fuel filter) it might crank for a while but it will go, if not check all plugs on injectors and TPS etc etc, if need be spray the insides of the plugs with some wd40 and it will probably idle a bit funny to start with but it will/should settle back to norm give or take.

Again, if you think you cant complete this job on your own or do it safely, DON’T

Get someone to help you or do it for you.

But I strongly advise new injector seals are fitted, don’t chance the old ones, ive seen people fit them back despite what ive told them and they have leaked, and your hot exhaust is only 2 foot away, you want to take that chance for the sake of 20p per seal?? (£8 set from fords not including regulator)

Good luck and hope this guide helps.

Oh and the guild for fuel pump fit fitment is the same for all EFI’s and CFI’s.